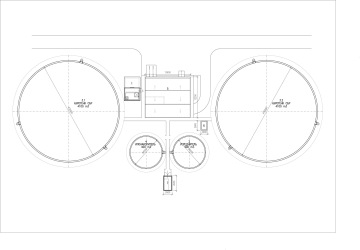

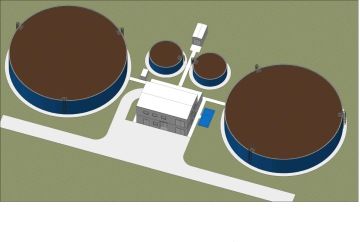

Domestic life and any production that uses water resources in the process of work is faced with the need to treat wastewater. The main problem is that very stringent requirements are imposed on wastewater, and modern high-quality water treatment equipment is expensive. To minimize equipment costs and maintain profits, it is necessary to achieve an optimal price-quality ratio, which is what we achieve when developing our projects.

Dvorak-engineering develops and implements wastewater treatment projects:

- production /industrial - wastewater generated in the technological processes of production

- household / domestic - wastewater generated as a result of human household activities

-

surface wastewater - rainwater and melt-formed during the melting of snow, ice

-

wastewater generated during the operation of the HSU

There is a variety of cleaning methods that can be divided into the following main groups according to the main principles used:

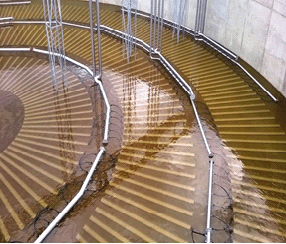

- mechanical ones are based on the procedures of filtering, settling, inertial separation. It allows to separate insoluble impurities. In terms of cost, mechanical cleaning methods are among the cheapest methods.

-

chemical ones are used to isolate soluble inorganic impurities from wastewater. When treating wastewater with reagents, they are neutralized, decolorized and disinfected. During the chemical cleaning process, a fairly large amount of sediment can accumulated.

- physical and chemical processes of coagulation, oxidation, sorption, extraction, electrolysis, ultrafiltration, ion-exchange purification and reverse osmosis are used. This is a high-performance purification method that allows you to purify wastewater from fine and coarse particles, as well as from dissolved compounds.

-

biological - these methods are based on the use of microorganisms that absorb wastewater pollutants. Biofilters with a thin bacterial film, biological ponds with microorganisms inhabiting them, aeration tanks with activated sludge from bacteria and microorganisms are used. To support the biological treatment process, all process conditions must be met: temperature, pH, oxygen, etc. To do this, it is necessary to provide the dosage of reagents (H2SO4, NaOH), carbon source (ethanol, methanol) and iron sulfide.

Combined methods are often used, using different cleaning methods at several stages. The use of a particular method depends on the concentration and harmfulness of impurities.